Automotive - Production Facilities

In order to fulfill the changing needs of our clients, we offer comprehensive production facilities, with high investments in robotic machineries and semi-automated assembly lines which are complemented by the latest range of testing and measurement equipment to ensure quality products at all times.

Plastic Injection Machines are used for producing a variety of parts by injecting materials into a mould. We have a wide range of these machines, ranging from 30 to 3000 tons to cater for products of various size and dimensions.

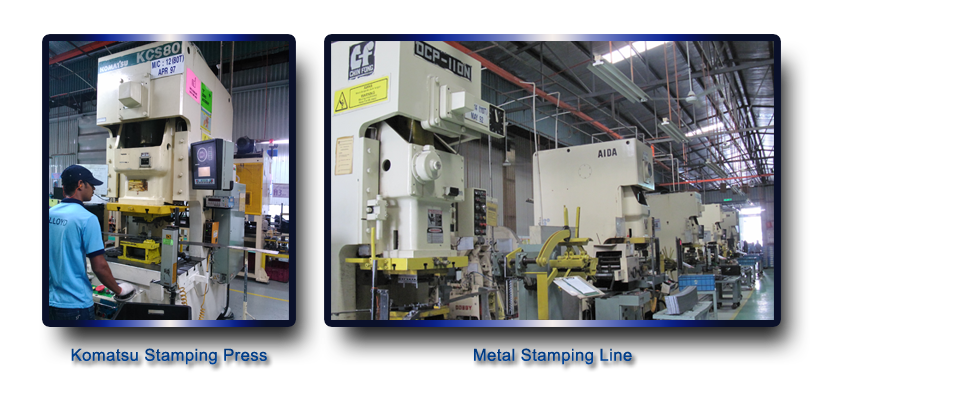

Metal Stamping Machines are used to transform flat sheet-metal into shapes / parts in volume. We have stamping machines, ranging from 45 to 150 tons with various processing methods such as squeeze, pinch, bend and etc.

Our Robotic Painting Line consists of robotic arms in various configuration (such as primer coat, base coat and clear coat) and lifter oven system to meet accurate and consistent paint finish quality.

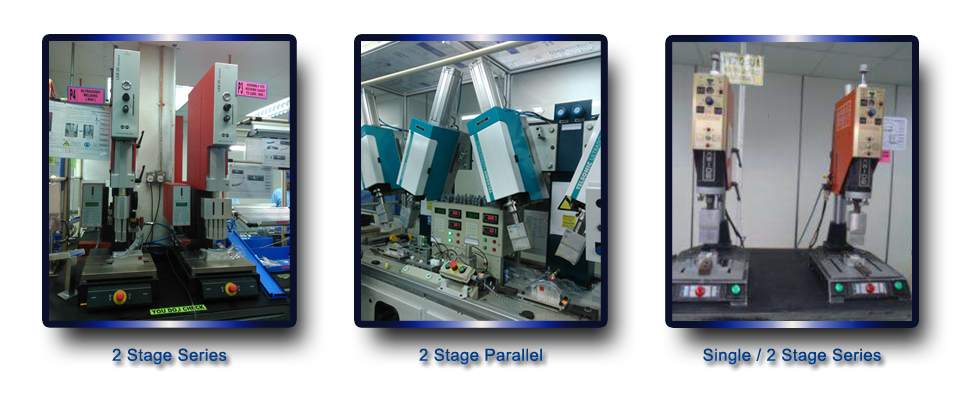

Ultrasonic Welding Machines are used for joining / welding operations of thermoplastic parts.

Product: Side Turn Signal

High Frequency Welding Machines are used for joining / welding together sheets of PVC and PU using an electromagnetic field.

Product: Sunvisor

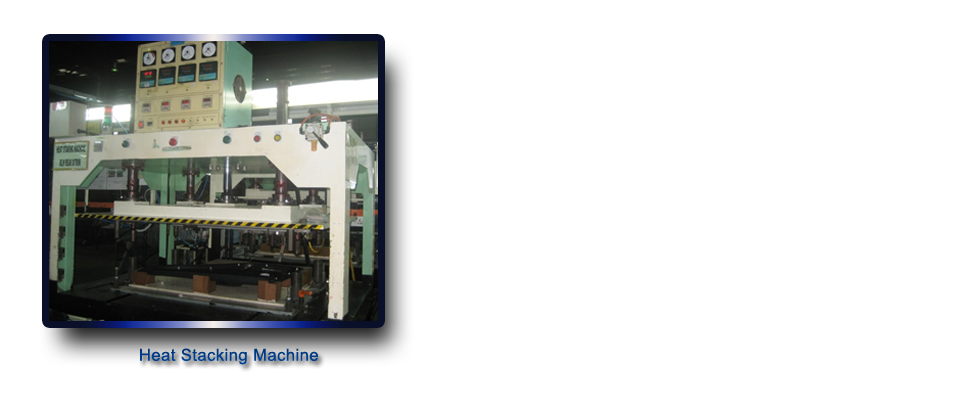

Heat stacking is used to join plastic components together.

Product: Door Trim

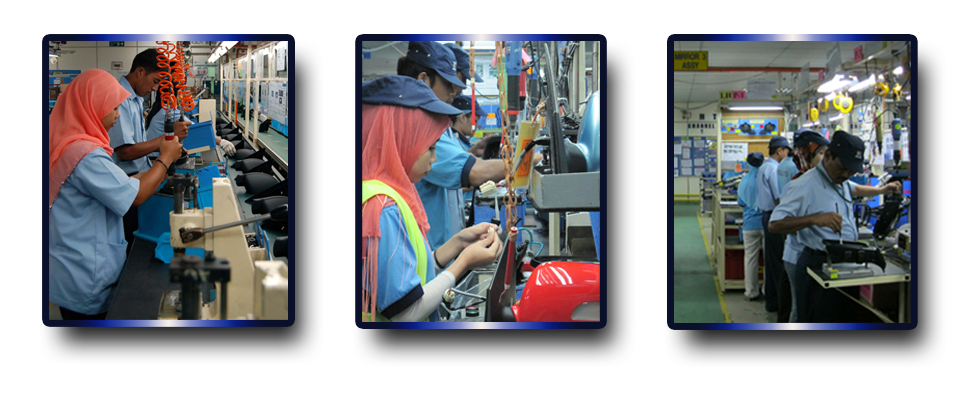

An Assembly Line is a manufacturing process in which parts are added to a product in a sequential manner to create an end product. We have a sizeable number of assembly lines at different locations to produce our range of products.

'

'