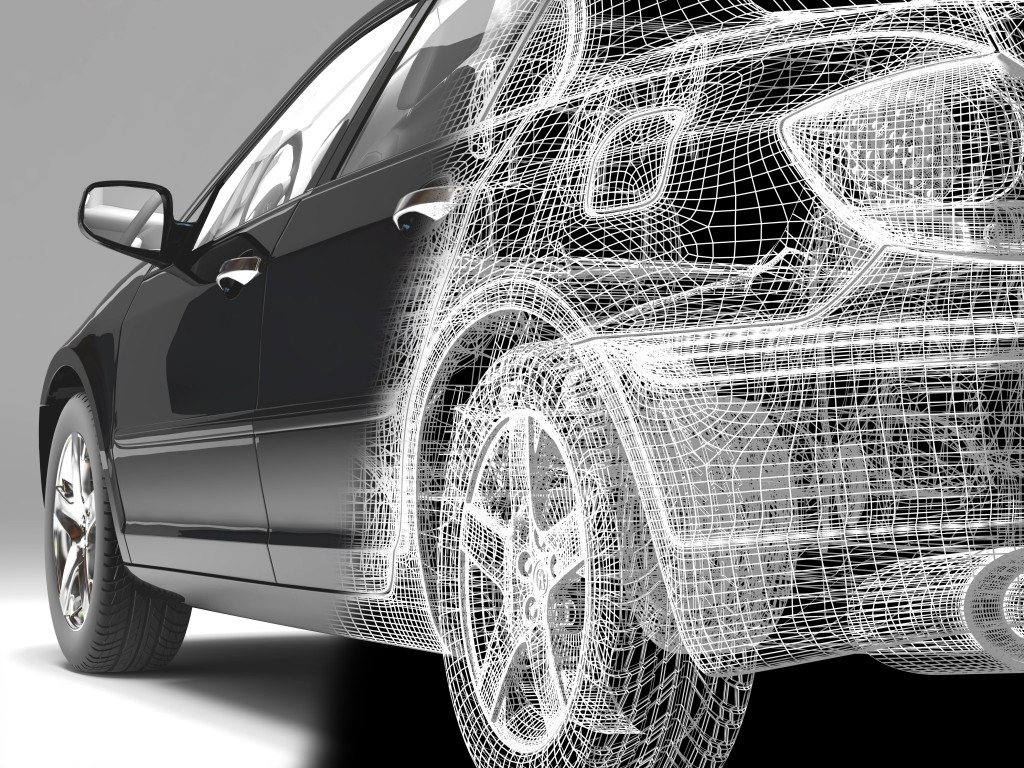

Automotive - Research & Development

Our comprehensive and state-of-the-art R&D facilities and engineers enable us to transform customers' concepts into finished products, while adhering to international quality standards. We have the capability to birth drawing designs from an idea or concept and develop a prototype and finally transformed into a ‘finished product’.

Our comprehensive and state-of-the-art R&D facilities and engineers enable us to transform customers' concepts into finished products, while adhering to international quality standards. We have the capability to birth drawing designs from an idea or concept and develop a prototype and finally transformed into a ‘finished product’.

Our R&D team consists of more than 40 qualified and experienced engineers who have the capability to cover all the elements in the life cycle of Delloyd's products which include the following:

Project Management ensures that project development initiative is a technical success, is on time and is professionally cost-managed. Delloyd R&D uses APQP (Advanced Product Quality Planning) to plan, manage and track all the phases of the product development up to series production.

Product development entails the refinement of ideas into processes and in doing so is able to bring a vast amount of knowledge to any R&D project which in turn enable us to produce a better product in a shorter time and with less expense.

Product development entails the refinement of ideas into processes and in doing so is able to bring a vast amount of knowledge to any R&D project which in turn enable us to produce a better product in a shorter time and with less expense.

Tooling is an integral part of the Delloyd R&D design to ensure cost-effective manufacturing with greater design flexibility, shorter lead time, and increased control over the quality and performance of the final product. The tooling concept includes tool-making approaches that apply additive, subtractive, and pattern-based processes.

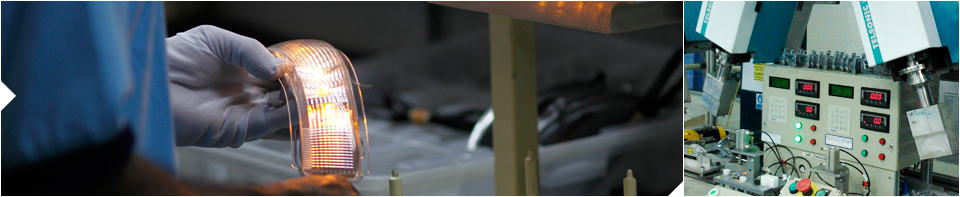

The Power Of Collaboration (Technical Assistance)

In our quest for technological advancement, we have collaborated with technical partners from Japan, Taiwan, Korea and Germany to garner cutting edge technology for the manufacture of new products.

With the technical know-how and knowledge put to work in our manufacturing and assembly plants, we are confident and capable to offer technical assistance to others in the automotive parts and components industry.

'

'