Automotive - Quality Control

Delloyd is committed to design and manufacture quality products at optimal cost through our continuous pursuit of excellence to meet customer satisfaction.

Delloyd is committed to design and manufacture quality products at optimal cost through our continuous pursuit of excellence to meet customer satisfaction.

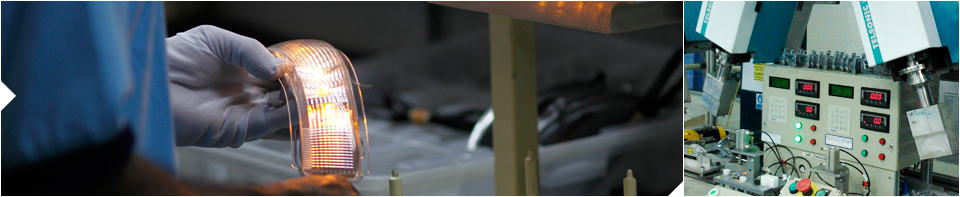

Quality is key in our business, and to ensure that only high quality products carry the Delloyd name, we are equipped with semi computerized systems and machineries, complemented by the latest range of testing and measurement equipment.

Delloyd’s final products are checked electronically and manually before delivery to customers. All goods are packed and properly sealed accordingly to customer's requirement.

Other Tester:

| Heat Aging Oven | Steel Ball Drop Tester | Mirror Lens Distortion Jig |

| Salt Spray Tester | Rockwell Hardness Tester | Wear Resistance Endurance Tester |

| Tensile Strength Tester | DAQ Vibration Tester | Impact Tester |

| Water Jet | Melf Flow Incex (MFI) | Bending Tester |

| Column Switch Endurance Tester | Power Window Endurance Tester | Power Folding Endurance Tester |

| Actuator Door Latch Endurance Tester | Cancel Cam Tester | Wheel Cover High Speed Turning Tester |

| Side Turn Endurance Tester | Heater Function Tester | Heat Resistance Endurance Tester |

| Detachment Endurance Tester | Sunvisor Endurance Tester |

Delloyd Quality Management team conducts in APQP for product quality verification. This activity is to assure the desired product quality during development stage.

Functional testing of products is performed at the last phase of the production line, as a final quality control to ensure that our products fulfill its functional specifications.

Other Tester:

| Column Switch Final Tester | Garnish Tester | Center Switch Tester |

| Cluster Switch Tester | Passenger Airbag Tester | Door Switch Tester |

| Door Latch Auto-lock Tester | Latch Actuator Tester | L02B Regulator Function Tester |

'

'